How to Choose the Right Wire Gauge for Trailer Wiring

Share

Introduction

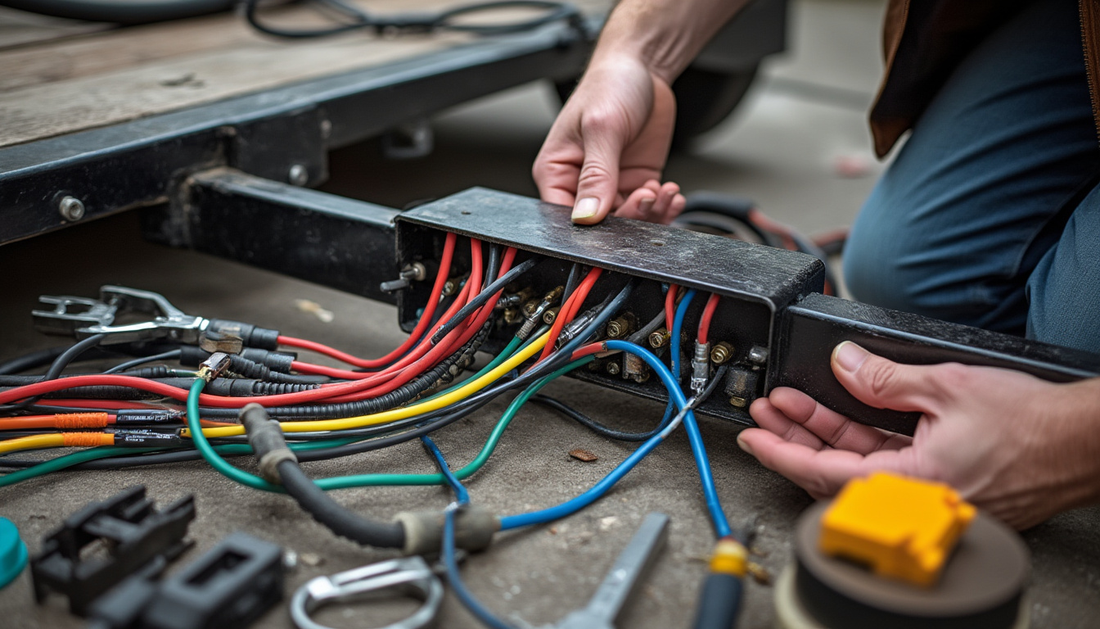

Choosing the right wire gauge for your trailer’s electrical system is vital for safety, efficiency, and reliability. From powering trailer lights and brakes to charging batteries, the wire gauge you use affects everything. Incorrect wire sizing can result in voltage drops, equipment malfunction, overheating, and even fires. This guide will help you understand how to select the appropriate wire gauge for your trailer wiring needs.

Why Does Wire Gauge Matter?

Wire gauge refers to the thickness of the wire, and it’s measured using the American Wire Gauge (AWG) system. The lower the number, the thicker the wire and the more current it can carry. For trailer wiring, selecting the correct wire gauge ensures that your system operates without overheating or voltage drops, which can lead to electrical failures.

Key Factors to Consider When Choosing Wire Gauge

1. Current Load

The most critical factor when choosing wire gauge is the current load, measured in amps. Different components of your trailer’s electrical system—lights, brakes, batteries—draw different levels of current. The more current required, the thicker the wire needs to be to safely handle the load.

2. Wire Length

Longer wire runs increase resistance, leading to voltage drop. This makes it necessary to use a thicker wire gauge for longer connections to ensure that sufficient voltage reaches the component at the end of the wire.

3. Wire Type

For trailer wiring, copper wire is the most common choice due to its excellent conductivity and durability. Copper-clad aluminum (CCA) is another option, although it has lower conductivity and is less durable, so you may need a thicker gauge if using CCA.

4. Wire Insulation

Wire insulation protects the conductor from damage, weather, and other environmental factors. Trailer wiring should use weather-resistant insulation, especially if it will be exposed to moisture, dust, or high heat.

Common Wire Gauges and Their Functions in Trailer Wiring

The table below outlines the recommended wire gauge for different trailer functions, wire color coding, and where the wires should connect between the vehicle and the trailer.

| Wire Gauge (GA) | Wire Color | Function | Current Load (Amps) | Connection Point (Vehicle) | Connection Point (Trailer) |

|---|---|---|---|---|---|

| 10 GA | Black/Red | Auxiliary Power/Battery Charge | 31-40 amps | Vehicle battery/auxiliary power | Trailer battery or accessory ports |

| 12 GA | Blue | Electric Brake Control | 21-30 amps | Brake controller | Trailer brake system |

| 12 GA | White | Ground Connection | Grounding system | Vehicle frame/ground point | Trailer frame/ground point |

| 14 GA | Yellow | Left Turn/Brake Light | 16-20 amps | Vehicle left turn/brake light | Trailer left turn/brake light |

| 14 GA | Green | Right Turn/Brake Light | 16-20 amps | Vehicle right turn/brake light | Trailer right turn/brake light |

| 16 GA | Brown | Tail Lights, Running Lights | 10-15 amps | Vehicle tail light harness | Trailer tail lights, running lights |

Application-Specific Considerations

1. Trailer Lights

Trailer lights, including tail lights, brake lights, and turn signals, usually operate with lower current requirements. For these, 16 GA or 14 GA wire is suitable. Each function, such as left and right brake lights or turn signals, is typically color-coded to make installation easier.

2. Electric Brakes

Electric trailer brakes require more current to function effectively. To handle this increased load, 12 GA or 10 GA wire is recommended. The blue wire typically handles the brake controller's output, connecting it to the trailer's braking system.

3. Battery Charging and Auxiliary Power

For charging a trailer battery or powering other accessories (like interior lights), use 10 GA wire to prevent voltage drop, especially for long runs. The black or red wire from the vehicle’s battery connects to the trailer’s battery or accessory ports.

4. Grounding

A proper ground connection is crucial for trailer wiring. Use 12 GA or 10 GA white wire to ensure a solid ground connection between the vehicle frame and trailer frame. This prevents electrical malfunctions and ensures consistent current flow.

Conclusion

Choosing the right wire gauge for trailer wiring is essential for safe and reliable operation. Be sure to consider the current load, wire length, and function of each component when selecting your wire gauge. Using the correct wire gauge will prevent issues like overheating, voltage drop, and electrical failure, ensuring your trailer operates smoothly. For most trailer wiring setups, following the color-coded system and adhering to gauge recommendations based on current load will simplify installation and ensure long-lasting performance.