Common Mistakes to Avoid When Working with Wire Gauge

Share

Introduction

Selecting and working with the correct wire gauge is a crucial aspect of any electrical or lighting project. The wire gauge determines the wire’s capacity to carry current, its resistance, and its overall performance. Making mistakes in this area can lead to inefficient power delivery, overheating, voltage drop, and even fire hazards. This blog will guide you through the most common mistakes to avoid when working with wire gauge, ensuring your projects are safe, efficient, and long-lasting.

1. Underestimating the Current Requirements

Calculating Current Draw Incorrectly

One of the most common mistakes when working with wire gauge is calculating the current draw incorrectly. The current draw, or amperage, is the amount of electrical current that flows through the wire. Miscalculating this can lead to using a wire gauge that is too small for the electrical load, resulting in overheating and potential fire hazards.

To avoid this mistake, it's essential to accurately determine the current draw of all the devices and components connected to the circuit. This involves adding up the current ratings provided in the specifications of each device. For instance, if you have five LED lights, each drawing 1 ampere, the total current draw is 5 amperes. Ensure you consider all devices, including any that might be added in the future.

Ignoring Peak Loads

Another critical error is ignoring peak loads. While the average current draw is important, peak loads, which are short-term spikes in current, must also be considered. Electrical devices, especially those with motors or heating elements, can draw significantly more current at startup than during normal operation.

2. Overlooking Voltage Drop

Failing to Account for Distance

Voltage drop is a reduction in voltage that occurs over the length of a wire due to its resistance. Failing to account for distance is a common mistake that can significantly affect the performance of an electrical system. The longer the wire, the greater the voltage drop, which can cause devices to receive insufficient voltage, leading to dimming lights or malfunctioning equipment.

To mitigate voltage drop, it's essential to calculate it for your specific application. As a general rule, for distances over 100 feet, a thicker wire gauge is required to minimize voltage drop.

Using Inadequate Wire Gauge

Using inadequate wire gauge is another frequent mistake. A wire gauge that is too small for the current it needs to carry can lead to excessive voltage drop. This not only affects performance but also increases the risk of overheating and fire.

3. Not Considering Environmental Factors

Temperature Effects on Wire Performance

Environmental factors play a significant role in wire performance. Temperature effects on wire performance are often overlooked. High temperatures can increase the resistance of the wire, reducing its current-carrying capacity. This is particularly important in environments where the temperature can fluctuate significantly or where the wire is exposed to heat sources.

Exposure to Moisture and Chemicals

Exposure to moisture and chemicals is another critical consideration. In environments such as outdoor installations or industrial settings, wires may be exposed to moisture, chemicals, and other harsh conditions that can degrade their insulation and performance.

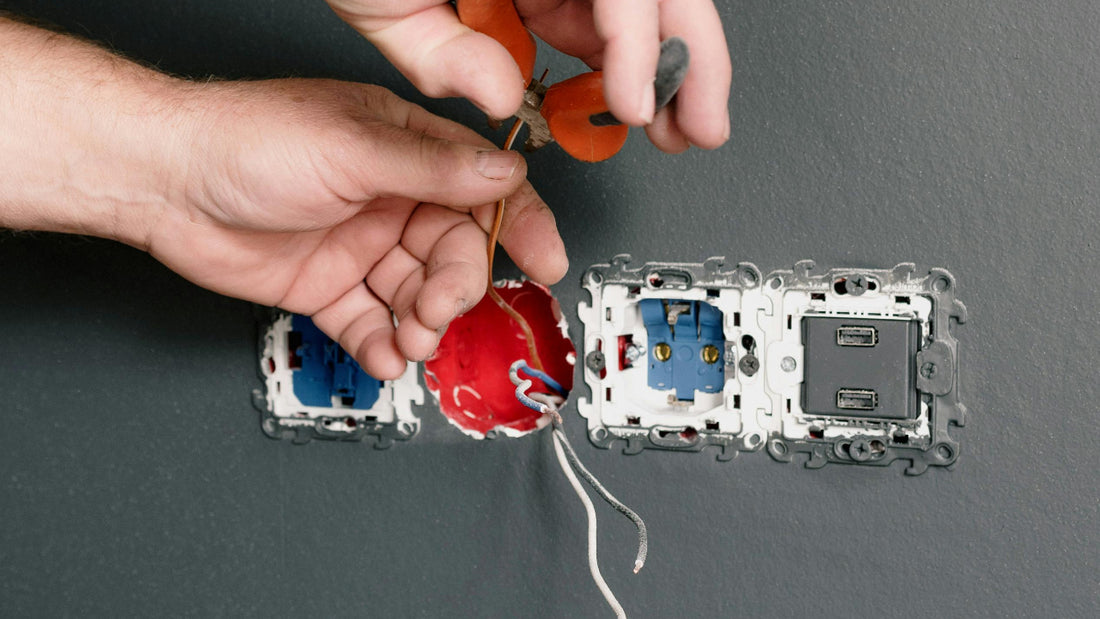

4. Improper Installation Practices

Loose or Poor Connections

Improper installation practices can undermine even the best wire gauge selection. Loose or poor connections are common issues that can lead to overheating, arcing, and potential fire hazards. Ensuring all connections are secure and free from corrosion is vital.

Overloading Circuits

Overloading circuits is another frequent mistake. Connecting too many devices to a single circuit can exceed the wire’s current-carrying capacity, leading to overheating and potential damage. To prevent this, calculate the total wattage of all connected devices and ensure it does not exceed the circuit’s capacity.

5. Using Low-Quality Materials

Choosing Cost-Effective Wires

In an effort to cut costs without compromising performance, many turn to choosing cost-effective wires like Copper-Clad Aluminum (CCA). While CCA wires have higher resistance than pure copper, they offer a balance of performance and affordability, making them suitable for many applications.

Ignoring Manufacturer Specifications

Ignoring manufacturer specifications is another critical mistake. Each electrical component and wire comes with manufacturer guidelines regarding its use, capacity, and installation. Failing to adhere to these specifications can lead to inadequate performance and potential hazards.

6. Failing to Plan for Future Expansion

Underestimating Future Needs

One of the common mistakes in wiring projects is underestimating future needs. While the current requirements might be met with the selected wire gauge, future expansions or additions could exceed the capacity of the wires.

When planning your wiring project, consider potential future expansions. Choose a wire gauge that not only meets the current demands but also has some capacity to handle additional loads in the future. This proactive approach can save time and money and prevent the need for extensive rewiring later.

Not Leaving Room for Upgrades

Not leaving room for upgrades is closely related to underestimating future needs. Electrical and lighting technologies are constantly evolving, and newer devices may require higher current or different wiring configurations.

By selecting a slightly thicker wire gauge than currently necessary, you provide flexibility for future upgrades. This ensures that your wiring system remains robust and adaptable to new technologies and requirements.

Conclusion

Working with wire gauge requires careful consideration of various factors to ensure safety, performance, and longevity of your electrical and lighting systems. By avoiding common mistakes such as underestimating current requirements, overlooking voltage drop, ignoring environmental factors, practicing improper installation techniques, using inadequate materials, and failing to plan for future needs, you can create a reliable and efficient setup. Embracing cost-effective solutions like CCA wires can further enhance your project's value without compromising on quality. With proper planning and attention to detail, you can achieve optimal results in your wiring projects.